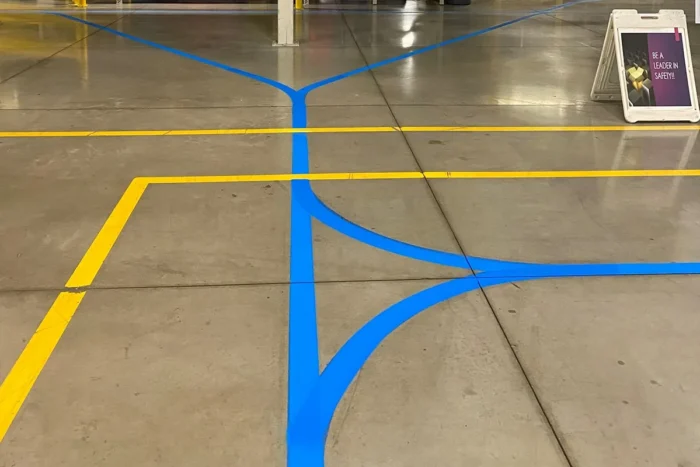

At Nu-Line Pavement Marking, we provide professional warehouse striping that keeps your facility organized, safe, and compliant. From small storage facilities to large distribution centers, our team installs clear, durable lines that guide traffic, define work zones, and improve overall operational efficiency. Proper industrial floor markings reduce accidents, ensure compliance with OSHA and safety standards, and help your team work smarter—not harder. We use high-quality paints and thermoplastics that withstand forklifts, pallets, and heavy daily traffic, so your markings last longer and require less maintenance.

Contact us to request a quote or schedule your warehouse striping project.

Key Warehouse Striping Services We Offer

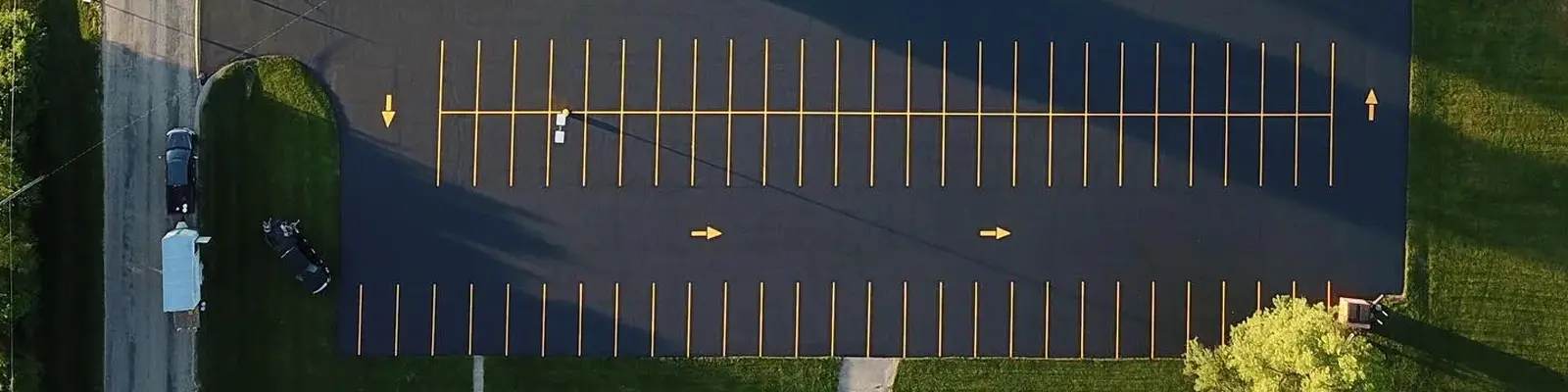

Aisle & Pathway Markings – Clearly define safe travel routes for forklifts and pedestrians to reduce accidents and improve workflow efficiency.

Forklift & Equipment Zones – Mark storage and operational zones to prevent collisions, protect equipment, and optimize industrial operations.

Safety & Hazard Markings – Highlight high-risk areas, emergency exits, and fire lanes with durable paint and thermoplastic materials for maximum visibility.

Loading & Unloading Areas – Keep docks organized and accessible with clear, long-lasting markings that streamline loading and unloading operations.

Custom Layouts & Floor Designs – Tailored striping for complex warehouse layouts, including mezzanines, cross-aisles, and specialized storage areas.

Who We Serve

- Distribution Centers & Industrial Facilities – Reduce downtime, prevent accidents, and maintain smooth operations with well-marked floors.

- Manufacturing Plants – Ensure assembly lines, storage zones, and safety areas are clearly defined for worker efficiency and safety.

- Warehouses & Storage Facilities – Organized floors improve space utilization and make inventory management easier.

- Retail & Fulfillment Centers – Maintain high-traffic areas with visible pathways and designated zones for efficient operations.

- Contractors & Property Managers – Expert layouts that meet safety codes and improve facility flow for all clients across Kansas.

Why Choose Nu-Line Pavement Marking

- Decades of Local Experience – Trusted by Kansas industrial clients since 1995.

- Safety & Compliance Expertise – Layouts meet OSHA and industry-specific safety standards.

- Durable Materials & Techniques – Industrial-grade paints and thermoplastics that withstand heavy traffic, forklifts, and pallet jacks.

- Proven Industrial Results – From small warehouses to large distribution hubs, we deliver organized, professional results every time.

- Efficient Project Execution – Fast, reliable work that minimizes downtime and disruption to your operations.

Frequently Asked Questions

How often should warehouse striping be maintained or repainted?

Most industrial floors need touch-ups every 1–2 years depending on traffic and forklift use. Durable paint and thermoplastics extend the lifespan of your markings

Do you handle safety and hazard markings?

Yes. We stripe emergency exits, fire lanes, hazard zones, and other critical areas to ensure safety and compliance.

Can you stripe around ongoing operations?

Absolutely. We schedule work to minimize disruption and can work evenings, weekends, or off-hours.

What materials do you use for warehouse floors?

We use industrial-grade paints and thermoplastics designed for heavy traffic, forklifts, and pallet jacks, ensuring long-lasting results.

Do you provide customized layouts for unique warehouse needs?

Yes. We tailor each layout to your facility’s workflow, storage requirements, and safety standards.